Shut Off Valve Replacement Timing

Replacing shut off valves during routine inspections ensures early detection of issues and prevents unexpected failures.

Scheduling replacements in seasons with minimal plumbing activity reduces disruptions and allows for better access.

Replacing valves when they exhibit leaks or corrosion can prevent water damage and costly repairs.

Ways to make Shut Off Valve Replacements work in tight or awkward layouts.

Popular materials for Shut Off Valve Replacements and why they hold up over time.

Simple add-ons that improve Shut Off Valve Replacements without blowing the budget.

High-end options that actually feel worth it for Shut Off Valve Replacements.

Finishes and colors that play nicely with Shut Off Valve Replacements.

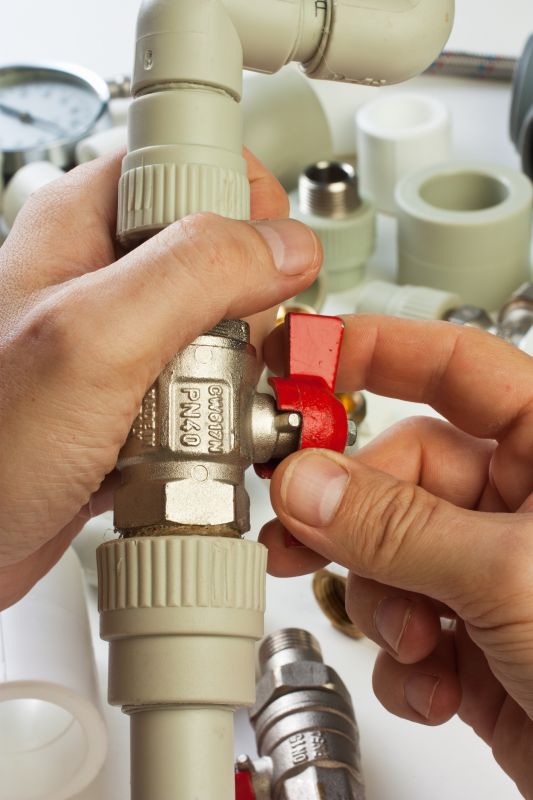

Shut off valve replacements are essential for maintaining plumbing system integrity and preventing water damage. Proper timing can extend the lifespan of plumbing components and reduce emergency repairs. Typically, replacements are recommended when valves show signs of corrosion, leakage, or difficulty in operation. Regular maintenance checks can identify these issues early, ensuring timely intervention.

Leaks, difficulty shutting off water, or visible corrosion indicate the need for replacement.

Off-peak seasons or during scheduled plumbing upgrades are ideal for replacements.

Options include brass, stainless steel, and plastic, each suited for different applications.

Ignoring signs can lead to pipe bursts, water wastage, and costly repairs.

Step-by-step installation ensures proper function and longevity.

Wrenches, pipe cutters, and sealing materials are essential for a secure fit.

Ball valves, gate valves, and globe valves serve different purposes in plumbing.

Corrosion can weaken valve integrity, necessitating replacement.

Identifying leaks early can save water and prevent damage.

Access points should be considered for easier future replacements.

Material choice, valve size, and installation complexity influence costs.

Ensuring proper operation after installation is critical for system reliability.

| Scenario | Recommended Timing |

|---|---|

| Valve shows signs of corrosion or leakage | Immediately or during scheduled maintenance |

| Planned plumbing upgrades | During upgrades for minimal disruption |

| Severe valve failure or inability to shut off water | As soon as possible |

| Routine inspection or maintenance | Every few years or as recommended |

| Property renovations or remodeling | During construction phases |

Timely replacement of shut off valves minimizes water wastage and prevents damage to plumbing infrastructure. Regular inspections and maintenance schedules can help identify the optimal moments for replacement, avoiding emergency repairs and ensuring system efficiency.